EXTERNAL SMALL DIAMETER

APCO External coating facilities are capable of applying both anti corrosion and protective coating systems subject to strict quality conditions with leading edge process technology. Employing advance real-time methods to monitor every stage of the coating application process APCO operations systems can ensure strict conformance to end user specifications. Finally, our facilities have been optimized to render the application conditions necessary to yield maximum performance from every coating system.

COATING LIMITATIONS

EXTERNAL SD (FBE/2LFBE/3LPE/3LPP)

| PROPERTY | SD EXTERNAL PLANT |

| Minimum Pipe Diameter | 50.8 mm (2.0″) |

| Maximum Pipe Diameter | 1625.6 mm (64.0″) |

| Minimum Pipe Length | 11.0m(36.0′) [FBE] / 11.5 m (37.8′) [3LPE/3LPP] |

| Maximum Pipe Length | 26.0 m (85.3′) [FBE] / 18.0 m (59′) [3LPE/3LPP] |

| Surface Finish | Sa 2½ |

The above values are given as general guidelines. For special requirements please consult APCO Commercial.

Coating Capability

FBE: Fusion Bonded Epoxy Powder Coating

High Temperature FBE: High Temperature Fusion Bonded Epoxy Powder Coating

2LFBE: Dual Layer Fusion Bonded Epoxy Powder Coating

3LPE: Three Layer Polyethylene Coating

3LPP:Three Layer Polypropylene Coating

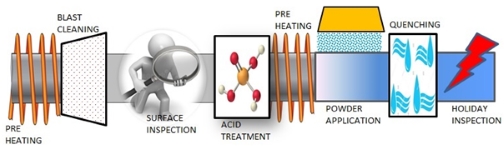

Application Process

3LPO Application Process

Single Layer FBE Application Process

Approvals

Health & Safety

APCO is committed in providing a safe, healthy workplace and ensuring that our business activities are conducted in a manner that protects the environment. It is our objective to achieve an Incident and Injury Free workplace, where everyone recognizes that by risking incident or injury, they are putting in jeopardy what they value and those they care for.