APCO LABORATORY & TESTING FACILITIES

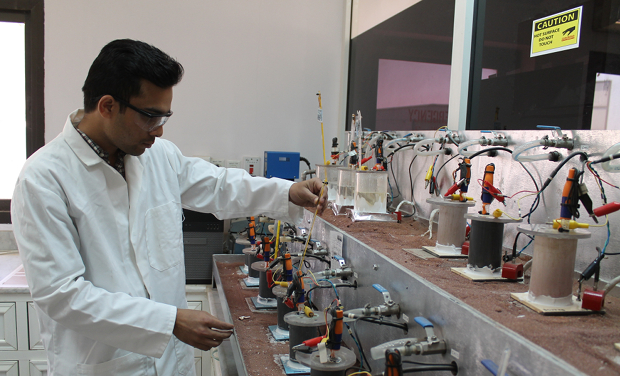

APCO line pipe & custom coated bends, spools, fittings & associated accessories coating facilities include two finished coated product Testing & Inspection Laboratories.

APCO’s Labs are fully equipped with the latest Oil & Gas Industry related equipment capable of performing the testing to verify that the finished coated product complies with & conforms to applicable International Standards & Client Specified Testing & Inspection requirements, that form an integral part of the APCO Finished Coated Product BS EN 10204 Certificate of Conformity.

Anti-Corrosion Protection Coatings Laboratory includes but is not limited to the necessary equipment to perform Fusion Bonded Epoxy, Liquid & Polymerized Thermoplastic Raw Materials Receipt Differential Scanning Calorimetry, Particle Size Sieving, Moisture Content, Gel Times, Melt Flow Indexing verification of material receipt conformity & is equipped to perform the finished coated product destructive testing Cathodic Disbondment, Flexibility, Hot Water Soak, Impact Resistance, Microscopic evaluation of cured film cross-section & interface porosity, & Cured FBE DSC Computer analysis, & Multi-Layer Polymer Coating Elongation, Penetration, On-Pipe Adhesion of the as applied coating performance verification testing.

APCO Field Joint Coating Mobile Lab shall be available for future project works during 2021

The testing is performed in accordance with various International Standards such as British BS EN ISO, Canadian CSA Z245, German DIN, French NFA, American API & ASTM aligned with individual client specified requirements, & in accordance with current APCO QMS ISO 9001:2015 certification mandated guidelines & requirements, noting that APCO is ISO 9001 continuously certified since 1997

Concrete Weight Coating Laboratory is comprised of fully equipped to perform the required Batching Plant & Full Pipe Weigh Scales Calibration, Concrete Mix Design, Fine & Coarse Aggregate Sieving, Water-Cement Ratio pre-production verification & as applied concrete coated pipe, OD Girth Measurement, Individual Coated Pipe Weight, Density, Submarine Negative Buoyancy, Full pipe Water Absorption Immersion, Compression Resistance Testing & Inspection verification as well as Destructive Shear Resistance, & Impact Resistance Testing.